Month: December 2015

At 15-years-old, Jennarong Muengtaweepongsa has created the new Koenigsegg Utagera Concept and unveiled it at the Bangkok Motor Expo. Yes, while most 15-year-olds are worried about learning how to drive a car, he designed one and has already worked with famous car designers.

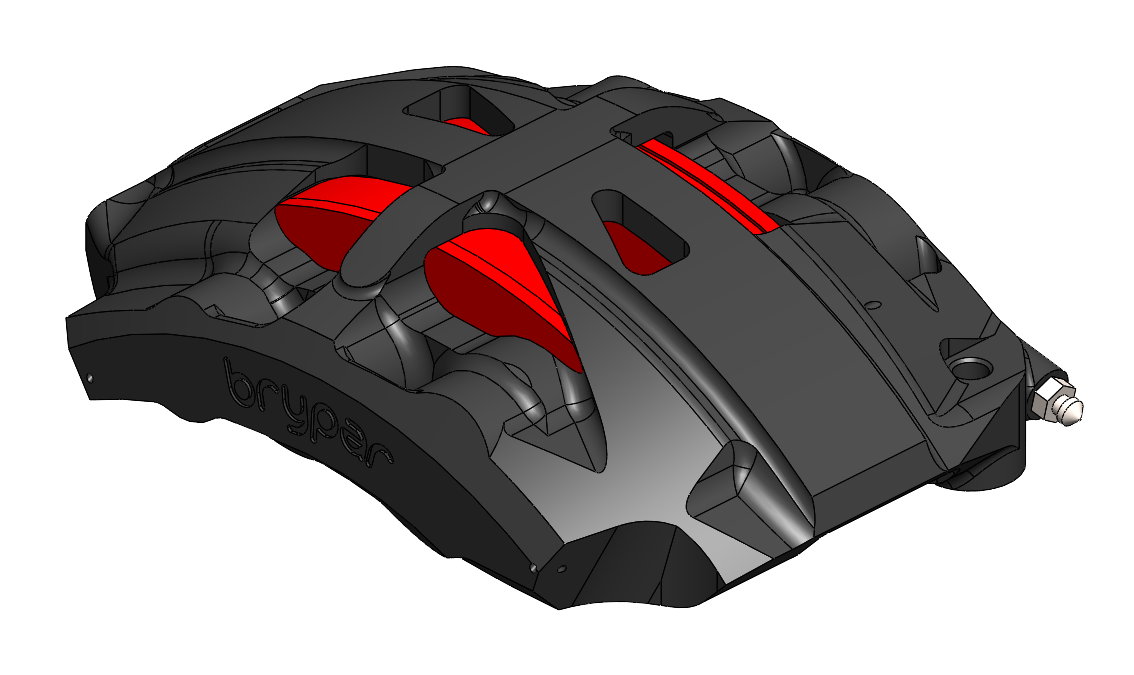

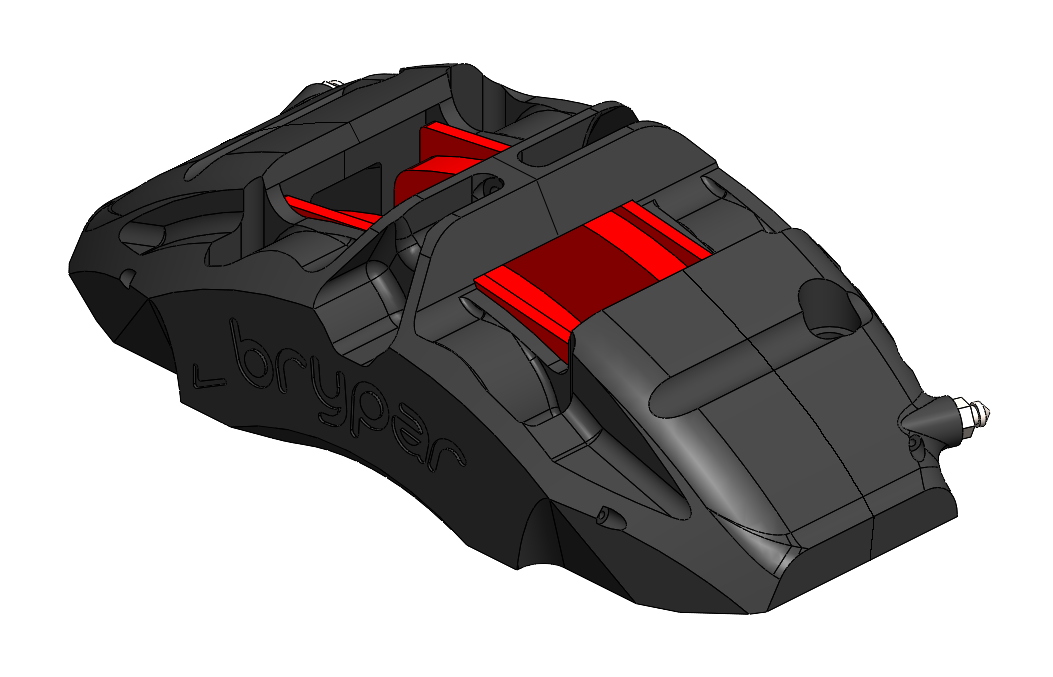

The car, like all Koenigseggs, features a smooth and curvaceous design that is highlighted by the wraparound windshield. He’s done a fanastic job taking Koenigsegg’s design cues and utilizing them in this brand-new concept. Brypar developed some special one-off concept brakes for the concept which will now feature exclusively on the talented young designers future creation.s

Currently, he’s hard at work creating different brand concepts and studying designs of multiple brands. The reason? He said he wants to find his own unique style.

What’s next for him? He says the next design he’ll release is the result of a collaboration with the ToBeUs toy car foundation and an Italian magazine. Be sure to follow him on Facebook and check out his website to learn more.

Brypar’s Nickel plating as seen above.

Brypar have been developing and testing our own specification and design of brake calipers for the last 12 months.

Unlike a lot of new brake brands on the market, we started from scratch. We researched, we tested, we made mistakes. But unlike others who simply rebrand someone else’s caliper, we designed from scratch every single element to ensure that we delivered the best caliper we could possibly deliver knowing every element inside that caliper was designed here in Australia by Brypar.

Unlike a lot of new brake brands on the market, we started from scratch.

Our Motorsport Calipers

Due to the special tooling required our first sets of motorsport calipers, a decision was made to manufacture them as a 2 piece design. We needed to ensure the critical seal area of the calipers were easily machined to the tight tolerances we required. Our own seals were manufactured locally from a unique European sourced motorsport grade material which offered better performance at elevated temperatures leading to longer service life as well as lower friction. Our pistons are machined from Grade 5 Titanium with built-in cooling cutouts – these help stop the heat transfer from pad to fluid. Other brands simply use caps on aluminium pistons – a cheap alternative. Finally we DLC coat the pistons for maximum durability. DLC coating is Diamond-Like Carbon – so our pistons will never suffer from scuffing. Behind the pistons sit stainless steel knock-back springs. Finally our calipers feature through cooling designed into the body to allow the caliper to remain cool in the heat of competition and our Nickel plating means the calipers remain durable and scratch resistant, unlike the anodising featured on many of our competitors.

While our range have taken longer than expected through the design and testing stages we now have an Australia made product that can proudly sit on the world stage. In 2016 we will be releasing a full range of billet monobloc motorsport brake calipers in materials that are usually reserved for Formula 1 and WEC. From open wheelers to fully fledged sports cars, from production racing cars to sports sedans, our range will have a caliper to suit.

Our Road Kits

Brypar’s road range of brake kits are an essential part of the Brypar brake line-up. Using the results from the research put into our motorsport brake calipers we have designed 2 road based brake calipers that feature any of the same design details as their motorsport relatives. Unlike many competitors so called road kits, ours are fully ADR approved for road use. Our kits come complete with fully floating discs, ADR approved braided lines, Australian Circo road/race brake pads and all other hardware required to bolt to your exisiting vehicle.

The brake calipers themselves feature internal fluid lines as well as cooling cutouts and the amazing Nickel plated finish. In 2016 these kits will be released to suit a small range of current models with more appearing as demand increases. Contact us today.

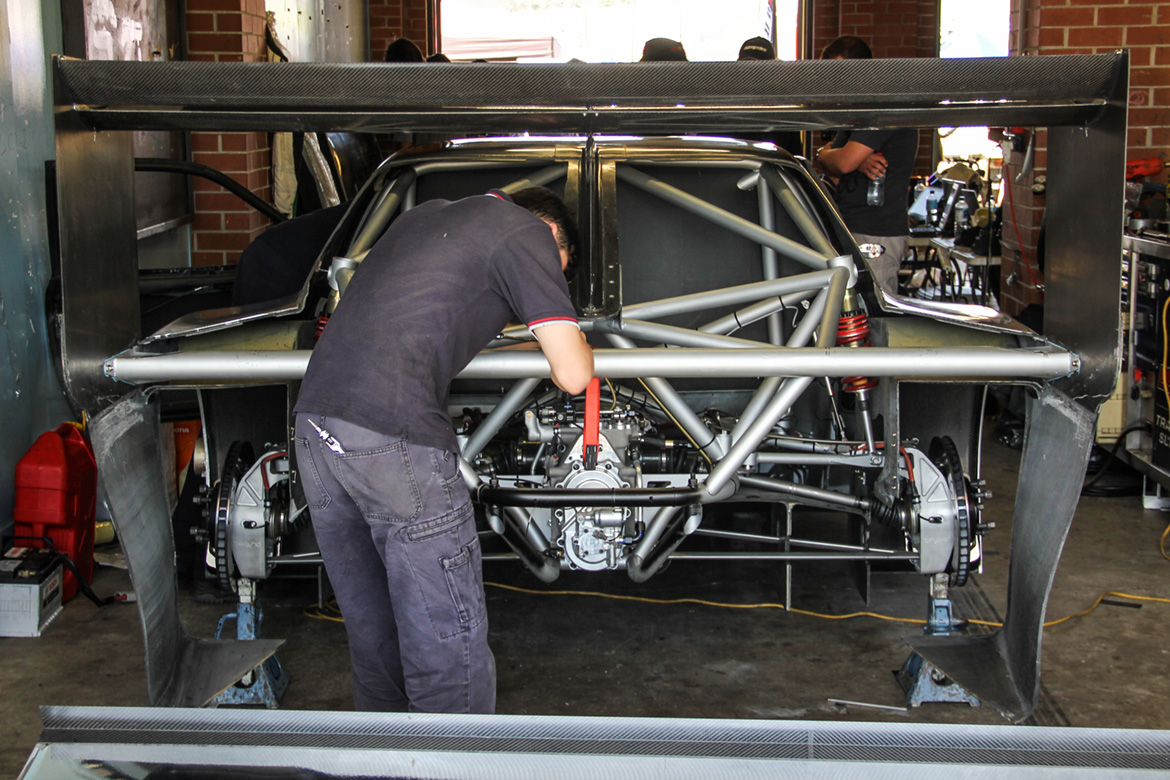

Late in 2014 after Brypar was formed we received a phone call from a potential customer enquiring about our universal uprights they’d seen at the 2014 World Time Attack Challenge at Sydney Motorsport Park. Little did we know this project would turn into one of the most comprehensive WTAC builds the world had ever seen. Initially we were to use our Universal Pro upright – a Porsche motorsport bearing housed upright aimed at the motorsport market, but due to the client having already purchased a complete set of brakes and hubs from a Porsche 991 Cup Car this meant there was no option but to design a set from scratch. Initially the brief was to design a universal centre section that could take a bolt-on steer arm, as well as bolt-on upper and lower mounts. We felt this type of design was too much of a compromise and offered a billet monobloc as a solution. Not only was the monobloc lighter, but it was much stiffer too.

Envirage had specified their own data points for Brypar to work with, meaning we were not involved in the kinematics side of the project. Simulations allowed these point to be fixed with very limited adjustability available, this also saved weight in the final design.

The car was completed just in time for the 2015 WTAC and although it did not have a chance to run in full anger still placed 4th outright with a 1:26 lap time – amazing considering the car caught fire on Thursday, broke the rear wing on Friday and had engine issues on the Saturday. The Brypar uprights easily withstood the immense aero loads the car was producing.

We are currently working with a number of teams building cars for the 2016 WTAC, and we believe RP968 will be back in 2016 in a much stronger position ready to challenge for the title.